Key characteristics of fused silica glass

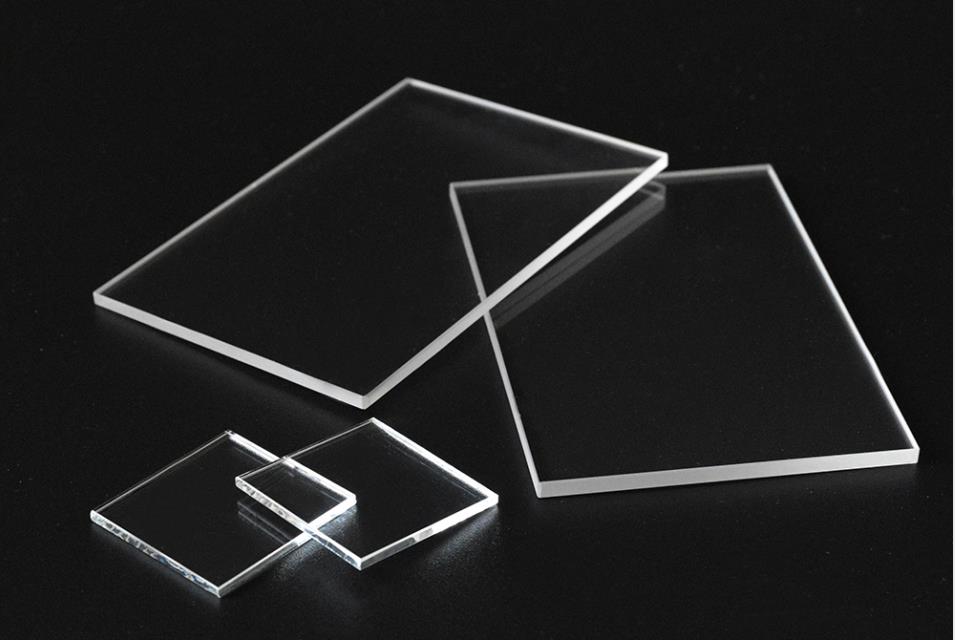

The key characteristics of fused silica glass can be reflected from multiple dimensions such as physics, chemistry, thermology, optics, etc. These characteristics make it irreplaceable in high-end manufacturing field.

Fused silica glass is an inorganic non-metallic material with excellent performance. Its key characteristics are as follows:

In terms of physical properties, its coefficient of thermal expansion is extremely low, about 0.5 × 10 ⁻⁷/℃ (20-300 ℃), and it has strong thermal shock resistance. It is also not easy to crack even when rapidly cooled at 1000 ℃; The Mohs hardness reaches 6.0, which is wear-resistant and has high strength. The bending strength is 100-150MPa, and the density is only 2.21g/cm ³, combining lightweight and high stiffness.Thermologically, its melting point is 1713 ℃, and it can be used for a long time above 1000 ℃. Its thermal conductivity at room temperature is as low as 0.7W/(m · K), and it enhances heat conduction through radiation heat transfer at high temperatures, making it unique in performance.

The optical performance is particularly outstanding, with a full spectrum transmittance of over 90% in the ultraviolet 185nm to infrared 20 μ m range, over 95% in the visible light region, and a light absorption coefficient<0.01cm ⁻¹, suitable for high-end optical components.

Chemical stability is extremely strong, except for hydrofluoric acid and hot phosphoric acid, it is resistant to acid and alkali corrosion, with a purity of over 99.99%, metal ion content<1ppm, and no pollution risk in the semiconductor field.

In terms of electricity, the volume resistivity is greater than 10 ¹⁸Ω· cm, and the high-frequency dielectric loss is low, making it an ideal insulating material. In addition, it can be precision machined and formed with a bubble rate of<0.1/cm ³.Through annealing to eliminate stress, it can meet the requirements of nanoscale surface accuracy and is indispensable in cutting-edge fields such as semiconductors, aerospace, and optics.