Optical elements processing process steps and precautions

1.Material selection and cutting

In the first step of optical component processing,the appropriate optical material needs to be selected.Common optical materials include glass,crystal, polymer,etc.According to the specific use needs, select the transparency of the material,heat resistance, refractive index and other characteristics.

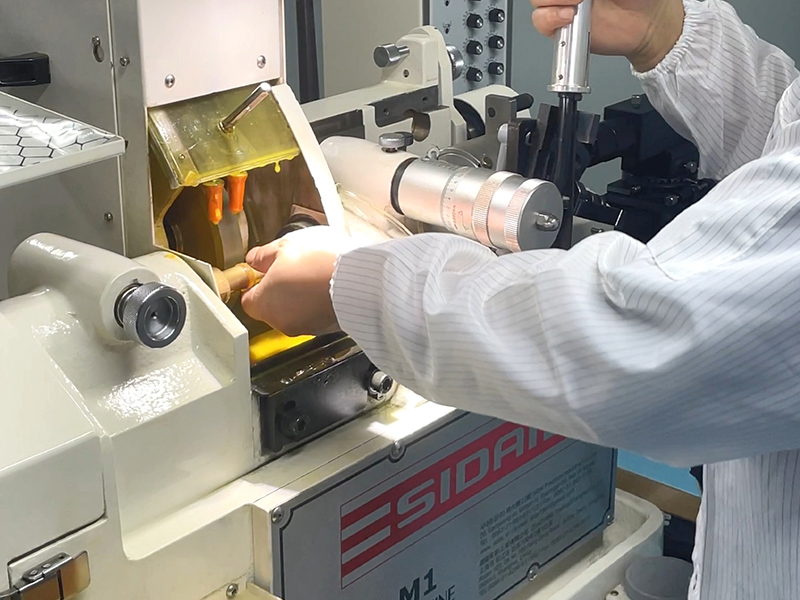

After selecting the material,the material is cut.The cutting process usually uses steel or diamond blades.When cutting,pay attention to the cutting direction and Angle,and ensure the flatness and smoothness of the cutting surface.

The cut material needs to be ground and polished to further improve the surface quality of the optical element.

During the grinding process,abrasives with coarser abrasive particles are first ground on the surface of the material to make the surface smoother and then gradually reduce the size of the abrasive particles until the desired smoothness is achieved.

Polishing is the further processing of the surface of the material after grinding to remove minor defects and scratches that may exist.The polishing process is usually carried out using polishing fluid and polishing cloth,and it is necessary to master the appropriate polishing pressure and speed to avoid excessive wear.

Optical coating is a processing step that is performed to increase the specific optical properties of an optical element.The coating process usually uses physical coating or chemical coating methods.

Physical coating deposited the thin film material uniformly on the optical element by evaporation or sputtering.Chemical coating is the use of chemical reactions to deposit the desired substance on the surface.In the coating process,it is necessary to control the deposition thickness and the uniformity of the film layer to meet the optical requirements.

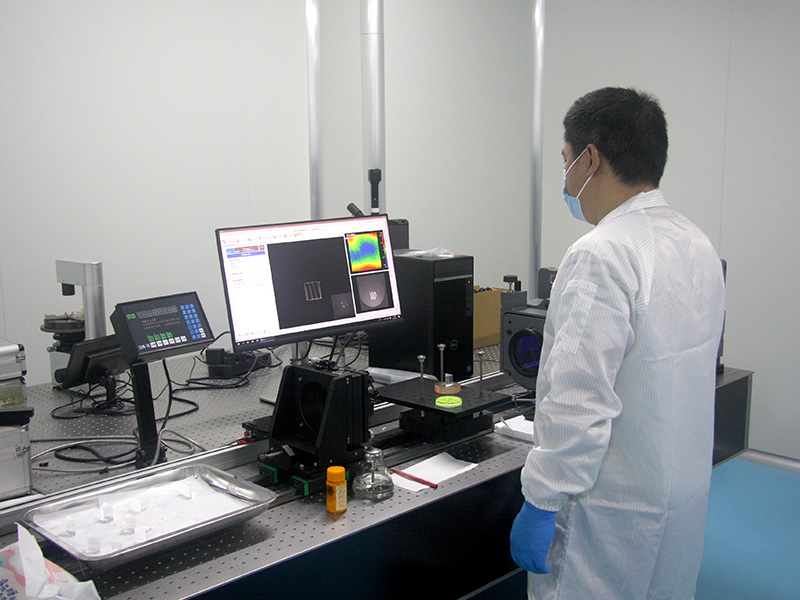

In the final stage of optical component processing,the quality of the finished product needs to be checked.The main content of quality inspection includes optical performance test, surface quality inspection and size measurement.Through these inspection means,it is possible to ensure that the optical component meets the specific quality requirements.Finally,optical components that meet quality requirements are packaged to protect their surface finish and avoid damage.

In the processing of optical components, the following aspects need to be paid attention to:

1.Temperature and humidity control

Optical materials are very sensitive to changes in temperature and humidity,so environmental conditions need to be strictly controlled during processing.

Too high or too low temperature,humidity may cause optical material deformation or damage.

Before grinding and polishing the optical component,the work surface, abrasive and polishing cloth need to be properly cleaned and treated to avoid contamination of the optical component surface.

The choice and use of grinding fluid has a great influence on the grinding process.The suitable grinding fluid can improve the grinding effect,and it is necessary to pay attention to the concentration of grinding fluid,PH value and cleaning method

Shenyang Ebetter Optics Co., Ltd. is a professional manufacturer of diffraction gratings and optical lens,optical window,prism,optical filter.We have rich experience in production and supply varied material of optical glass,CaF2,ZnSe,,silicon and sapphire products.