Zinc sulfide lenses: optical applications and development prospects

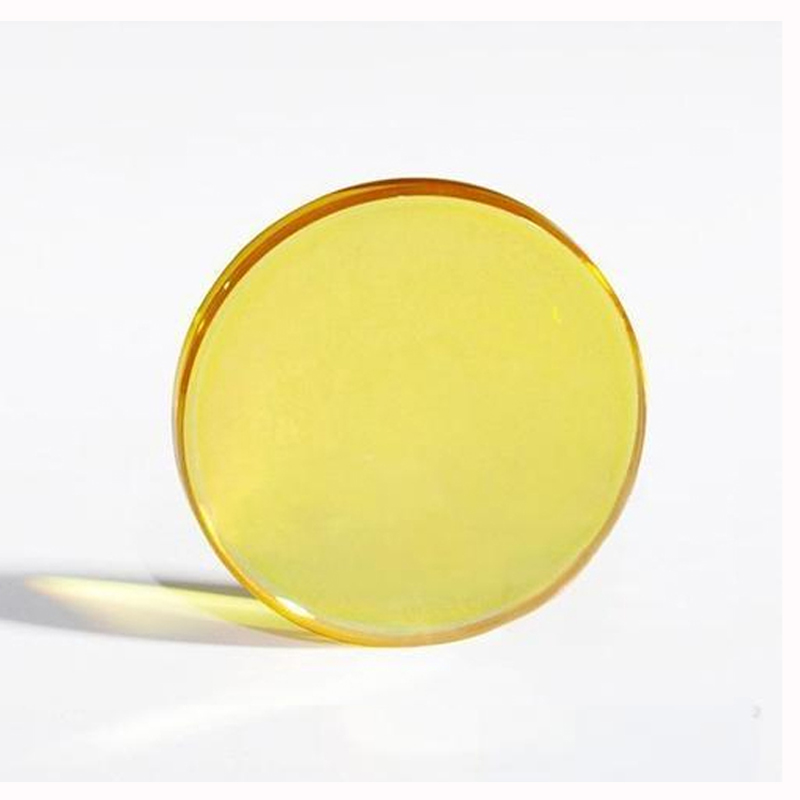

Zinc sulfide (ZnS) is an important material, which is widely used in the field of optics, especially in the manufacture of infrared optical lenses. Due to its excellent optical properties, zinc sulfide lenses are a key component in a variety of high-tech equipment, such as infrared imaging systems, laser equipment, and military and aerospace technology.

Basic characteristics of zinc sulfide lens

Zinc sulfide is a compound composed of zinc and sulfur elements, and the common crystal structure is a cubic lattice. Zinc sulfide lens occupies an important position in modern optical devices because of its unique physical properties, especially in the infrared band.High light transmittance: Zinc sulfide lenses have high light transmittance in the mid-infrared (MIR, 3-5 microns) and long-wave infrared (LWIR, 8-14 microns) bands. Compared to other common optical materials, zinc sulfide can transmit infrared light signals better, which is essential for infrared imaging and detection systems.

Good optical transparency: Zinc sulfide has a low absorption coefficient, which allows it to provide efficient light transmittance over a wide spectral range, thus effectively reducing light loss.

Heat resistance and radiation resistance: Zinc sulfide has strong thermal stability and high melting point, and can maintain its optical properties under high temperature or high radiation environment, suitable for applications under harsh conditions.

Low dispersion: The low dispersion of zinc sulfide means that in most applications, zinc sulfide lenses can maintain a relatively stable image quality and reduce aberrations due to dispersion.

Application field of zinc sulfide lens

Zinc sulfide lenses have important applications in many fields, especially in infrared optical systems.(1) Infrared imaging system

Zinc sulfide lenses play a crucial role in infrared imaging systems. Infrared imaging technology is widely used in military, security, medical and astronomical observation fields. Because of its excellent infrared transmittance, zinc sulfide is an ideal material for infrared thermal imaging lenses, especially in the mid-wave and long-wave infrared bands.

Military and security: In night vision equipment, missile guidance, and monitoring systems, zinc sulfide lenses are used to capture infrared images at night or in low-light environments to improve image clarity and recognition.

Medical imaging: Infrared imaging technology is widely used in medical diagnosis, especially in the early screening of diseases such as cancer and inflammation. Zinc sulfide lenses provide high-quality infrared images to help doctors make accurate diagnoses.

(2) Laser technology

Zinc sulfide lenses are also widely used in laser systems, especially in the focusing and conduction of laser beams. Laser technology has been widely used in communication, scientific research, industrial processing and other fields, and zinc sulfide lens can effectively focus laser beam and improve system efficiency.

(3) Environmental monitoring and detection

Zinc sulfide lenses are also used in the field of environmental monitoring, especially in gas detection, pollutant monitoring and so on. Using infrared spectroscopic analysis technology, zinc sulfide lenses can help equipment identify and analyze the characteristic absorption lines of different gases for accurate environmental monitoring.

Manufacturing and processing of zinc sulfide lenses

The manufacturing and processing technology of zinc sulfide lens is relatively mature, but it is difficult to process zinc sulfide material in practical application. Due to the high hardness of zinc sulfide, easy brittleness and easy oxidation in high temperature environment, special attention should be paid to the following aspects in the processing process:Polishing and surface treatment: The surface polishing of zinc sulfide lenses is a key step to improve optical properties. Fine polishing techniques are required to eliminate surface defects and optical distortions and ensure the optical quality of the lens.

High temperature treatment: Because zinc sulfide is prone to oxidation at high temperatures, it is necessary to use a special protective atmosphere during the processing, such as high temperature sintering in nitrogen or vacuum, to maintain the stability of the material and high light transmittance.

Coating technology: In order to further improve the anti-reflection performance of the lens, an anti-reflection coating is usually applied to the surface of the zinc sulfide lens. This can significantly reduce reflection losses, improve transmittance, and enhance the optical efficiency of the system.

With the continuous development of optical technology, the application field of zinc sulfide lens will be further expanded. Especially with the rapid progress of infrared imaging technology, laser communication and environmental monitoring technology, zinc sulfide as an important optical material has a broad prospect.