Laser Welding Galvanometer with water cooling refers to the use of a water cooling system to cool the galvanometer during the welding process of a galvanometer laser welding machine, in order to prevent equipment failure or errors caused by high temperatures.

The vibrating mirror laser welding machine can achieve instantaneous multi-point welding of the program by replacing the two-dimensional worktable with a moving scanning lens during the welding process, thereby improving production efficiency and flexibility. However, this highly efficient welding process generates a large amount of heat. If not cooled in time, it can cause thermal deformation of the vibrating mirror, affecting the welding quality and even leading to equipment failure.

Therefore, in order to ensure the accuracy and stability of laser welding, a water cooling system is usually equipped to cool the vibrating mirror. The water cooling system usually consists of a water cooler, water pipes, and joints. A water chiller can adopt an integrated 3P water chiller, with a temperature difference within ± 0.1 ℃. Water pipes and joints need to have characteristics such as high pressure resistance, high temperature resistance, and corrosion resistance to ensure long-term stable use.It should be noted that the water cooling system required for different models and brands of galvanometer laser welding machines may vary. Therefore, when selecting or using, it is necessary to choose and use according to one's own equipment model and actual situation.

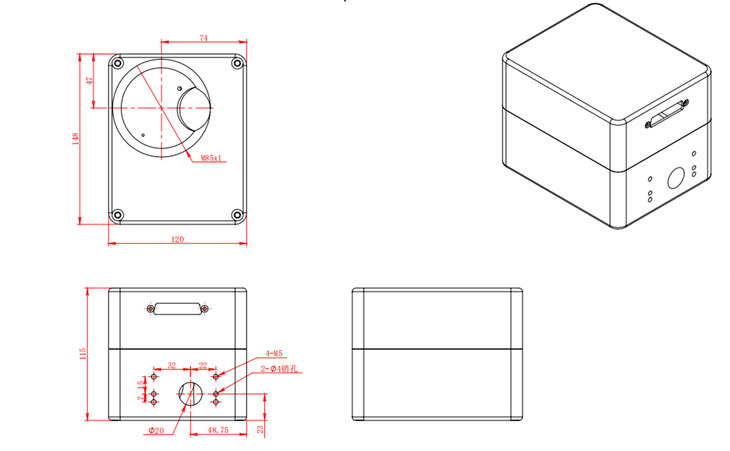

Laser Welding Galvanometer with water cooling

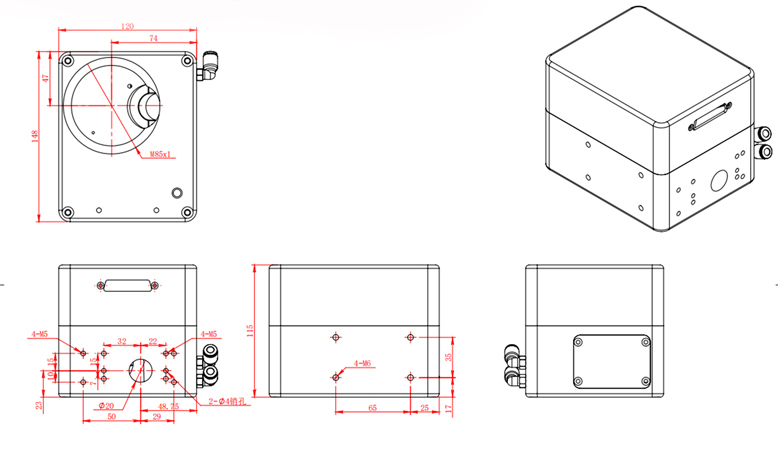

Laser welding galvanometer without water cooling